Technology

Steel panel-type radiator production

The Lemax produces steel panel-type radiators, complementing the line of heating boilers. A feature of LEMAX Premium radiators is that they are made from Russian steel on the Italian equipment. A well-established production process guarantees the reliability and efficiency of heating appliances.

Components of a successful radiator

In order for the radiator to meet the high requirements for modern appliances and to withstand the characteristics of Russian heating systems at the same time, there are three hallmarks:

- materials

- equipment

- technology

LEMAX Premium radiators are manufactured taking into account all three links.

Materials: steel, covering

Steel

Steel is an optimal material to produce radiators. It has a number of advantages over cast iron, aluminum and alloys:

- light weight;

- high heat dissipation;

- low inertia;

- affordable cost.

Covering

To produce LEMAX Premium radiators polyester primer and epoxy-polyester paint are used. They are distinguished by its bright white colour, excellent anticorrosion and decorative properties, which does not turn yellow during operation and retains a polish of 90%.

Equipment

The company has installed an automated welding line of the Italian concern LEAS, which is the leader in the production of welding automatics. LEAS company was founded in 1973 and started working with the production of welding lines for heating radiators - that is, this direction is leading in the activities of the concern. LEAS combines 40 years’ experience with the continuous introduction of innovations and thus keeps the position of the leader.

LEMAX Premium radiators are manufactured using the latest LEAS equipment. Only two operators manage a highly automated manufacturing process.

Production processes are controlled by electronic monitoring, human participation is necessary for equipment maintenance and interoperational and outgoing inspection of products. Only such a combination is the key to meeting the high demands of the market and world standards of quality.

Production: technologies and stages

The latest generated technology is used to produce LEMAX Premium radiators, and in every stage of production. In each stage of production, there is a concern for the quality of the finished devices.

Pressing

Pressing is the very first stage in producing radiators. Checkered sheets, of which later panel-type radiators are welded, are manufactured on unique presses. Compressing force equipped with complex-function arrays ranges from 60 to 630 tons. This technology ensures repeatability and geometric flawlessness of models.

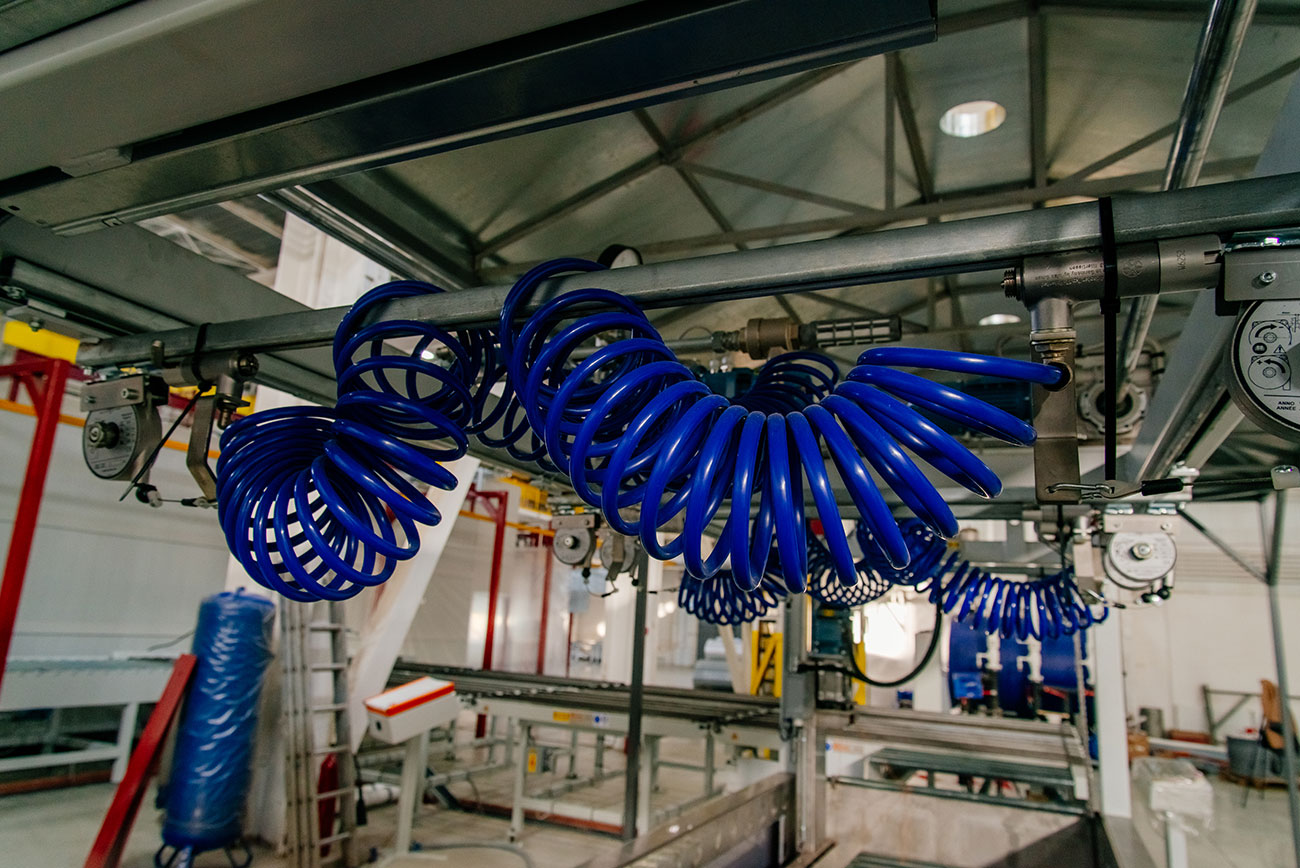

Welding operation

Elements of radiators are welded using the method of multipoint contact welding by currents of high and medium frequency. Radiator welding and edge cutting after welding takes place on a fully automated LEAS welding line. Stitches welded on this technology are characterized by high quality and reliability of joints.

Preparation for colouring

Surface preparation is the most important stage of production. LEMAX Premium radiators undergo multistage treatment before painting. It is based on titanium zirconium inhibition of corrosion with obligatory drying of the formed film in the oven at 120°C, which improves adhesion, check the growth of corrosion and extend the service life of the coating.

Padding

At the end of preparing the metal for painting, the radiators are padded. The drying of the ground coat is carried out in an oven at a temperature of 190 °C.

Colouring

Steel radiators LEMAX Premium are coloured with paint spraying in the electrostatic field. This method consists in the directed motion of paint granules along the lines of the electrostatic field, which guarantees maximum transfer of particles to the material, the stable ink anchorage of the paint to the surface. The process is completed by the polymerization of the paint in the oven at a temperature of 160 °C. The German painting equipment is used for electrostatic paint spraying. Coating LEMAX Premium radiators a unique powder epoxy-polyester paint is used.

Packing

Packing of radiators is carried out on an automatic line. For each radiator there are:

- individual liners for the protection of corners;

- double thermal shrinkage with a film;

- accessories for installation and passport;

- Individual serial number.

QC

Quality control is also carried out in several stages:

- Quality control of welding, which takes place at a control station of leak tightness. For monitoring, the radiator is connected to a compressed air system, immersed in a bath with a special solution and tested at a pressure that 1,5 times exceeds the working one.

- Interoperational control, during which the appearance, geometric dimensions and quality of assembling radiators are checked.

- Selective monitoring of radiators in the finished goods stock location. This examining is carried out by external auditors.

The multi-stage production and verification process is completely the same for all types of radiators produced by Lemax:

- with lower connection types 10, 11, 20, 21, 22, 30, 33;

- with side connection types 10, 11, 20, 21, 22, 30, 33.